Development basis and background

In recent years, with the rapid development of the communications industry, wearable devices have entered thousands of households and become indispensable for people's life, work and study. As a device in providing vibration output signals in wearable devices, flat vibration motors will develop in the following directions in the future: firstly, with the development of mobile phones in the direction of "light and thin", flat vibration motors are forced to be small and lightweight; Secondly, flat vibration motors pursue multi-function development to meet the multi-vibration mode development of wearable devices; thirdly, wearable devices develop in the direction of large picture and multi-function, the consumption of electric energy will increase, and the flat vibration motor will develop in the direction of continuous improvement of efficiency and power saving. Fourth, as the output of flat vibration motor continues to increase, motor manufacturing must adapt to mass production or automated production.

As the trend of wearable devices is ultra-thin, it is necessary for us to continuously improve the product structure, process and improve the performance of the product in terms of volume, weight, power consumption, start-up sensitivity, expansion of electromagnetic interference, etc., in order to meet the needs of the market and improve the company's competitiveness. In addition, the flat vibration motor can also be used in mobile phones, digital cameras, computer hard drives and precision medical equipment and other transmission mechanism, the use is very wide, the market prospect is very broad.

Main R & D contents and results

R & D content:

1. Provide a circular space inside the mutual docking. The central part of the upper and lower casings vertically fix the rotating shaft to support the rotation of the rotor. The rotor is equipped with two coils fixed on the commutator printed circuit board to generate magnetic field and a high specific gravity vibrator fixed on its upper part to form an integral flat structure.

2. The arc body of the vibrator shall be subject to the center of rotation and cover more than half of the upper part of the coil within a range of no more than 180 degrees. Under the rotor, permanent magnets with N-pole and S-pole arranged in a circular circle and a soft printed winding board connected to an external power supply are sequentially installed. One side of the brush is fixed to the soft printed circuit board and the other side contacts the commutator. The rotor is made of resin and high specific gravity metal vibrator on the upper part of the coil.

3. A wire groove is formed on the outer periphery of the bearing, and a step shape is formed on the outer edge of the vibrator to improve the structure firmly combined with resin injection molding. The hollow coil is also injection molded with resin, and the maximum procedure is to reduce the coil deformation caused by plastic pressure.

R & D Results:

1. We have developed a series of flat vibration motors with high energy density, strong practicability and high cost performance, which fully meet the needs of ultra-thin wearable devices.

2. A fully automatic assembly production line has been developed, which is fully integrated with rotor assembly, stator assembly, assembly and testing processes. The production line is equipped with advanced equipment, high degree of automation, good production continuity, reliable performance, high efficiency and safety, environmental protection and energy saving. At the same time, it is also very convenient to operate, adaptable, and able to adapt to the expanding market demand.

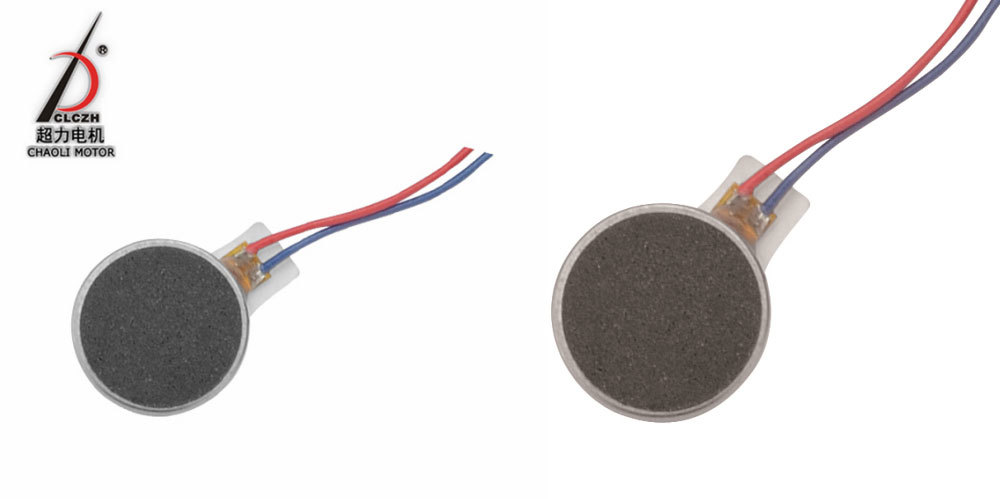

Legend of developed motor

Application Legend

Key words:

Previous Page

Previous Page

Guangdong Chaoli Motor Co.,Ltd.

Here is the title one h1 placeholder text

Address: Xingye East Road, Laimei Industrial Zone, Chenghai District, Shantou City, Guangdong Province

Shenzhen Sales Division

Name: Ms Hu

Mobile:(86) 138 2352 5969

Telephone:(86-755)2721 9096/2721 9696

Mailbox:szcl@chaolimotor.com

WeChat QR Code

Name: Mr. Cai

Mobile: (86) 136 7045 7762

Telephone:(86-754) 8696 2232

Mailbox:Henry@chaolimotor.com

Website:www.chaolimotor.com

WeChat QR Code

Name: Mr. Chen

Mobile:(86) 156 0271 1777

Telephone:(86-754) 8696 2230

Mailbox:cl@chaolimotor.com

Website:www.chaolimotor.com

WeChat QR Code

Main Products

Can't find the service you are looking for? Contact us!

If you need to inquire about our products, please leave your email to us and we will contact you within 24 hours.