Development basis and background

Personal vibration massager has a wide range of markets and applications in the market. At present, the new medium and high-grade electric massager has higher and higher performance and use requirements for its driving components. The speed, stability, noise, safety and life of the driving components largely determine the comfort and experience of the vibration grinder. The new hollow cup micromotor has many advantages of its own, it just meets its driving demand. It can be said that the research and development of hollow cup micromotors with high technical content and high added value has become the general trend. Through comparative research and at the same time at the request of customers, the company decided to carry out the research and development of 1015 mute high-torque hollow cup micromotors. On the one hand, it promotes the technological innovation of old products and expands the sales market. On the other hand, the innovation based on the new product series makes our company always take the initiative in the market, strive to research and development projects to boost the level of industrialization, bigger and stronger enterprises.

Main R & D contents and results

R & D content:

1. Process design of motor channeling structure based on low voltage start

The axial parts of the 1015 motor are designed for matching, and the amount of channeling is controlled within 0.1mm (other motors can be controlled within 0.5mm). At the same time, the elastic gasket is designed between the eccentric vibration and the motor. During the riveting process between the eccentric wheel and the motor shaft, the tooling is designed for shaft adsorption and self-adjustment in seconds, so that the motor can be started normally at 0.4V low voltage (the starting current is less than 25mA), it does not cause vibration and noise problems due to excessive amount of channeling, effectively solving the long-term process and production pain points.

2. Fast rotor coil shaping and winding optimization technology

By improving the winding chuck, a high-precision rotor manufacturing mold and tooling fixture are developed. According to the position of the magnet and the coil, the length of the six-sided straight line segment of the winding mold is 1/3 to 1/2 of the total length, and the optimal straight line angle is calculated to minimize the efficiency fluctuation. On this basis, the structure of the rotor coil itself is optimized, and the related motor performance parameter calculation software is used to compare the electrical performance before and after optimization 1015. Under the condition of meeting the motor speed, the no-load current of the whole motor after optimization is reduced, the torque is increased by more than 5%, and the efficiency is increased by about 3%.

3. Development of high-strength, high-efficiency micro-air-core cup motor winding insulation paint and shaping glue

Use a certain ratio (R-410 component a R-410 component B 410-X) (a 1 B 1 410-X1/3) to prepare insulating paint and bake the coil soaked in the paint in an oven at 130 ℃ for 160 minutes; Introduce 732 glue and 232 glue, and set the commutator and coil according to the ratio of 2:1 or directly use 232 glue. This greatly improves the coaxiality of the rotor, improves the dynamic balance performance, and effectively reduces the vibration that occurs when the motor runs at high speed.

R & D Results:

The whole 1015 hollow cup has reasonable structure and compact winding; the process is efficient, reasonable and advanced; the winding mechanism has high control precision, accurate cable arrangement and reliable operation. The quality of the winding coil is greatly improved, the vibration yield is increased by more than 10%, and the production efficiency is increased by more than 2 times;

2. Reach the established 1015 hollow cup micro motor key technology test index.

a. Noise ≤ 50dBA, without abnormal noise or noise;

B. Torque increased by more than 10% compared to the same volume core motor

C. other factory test and related type test: fully meet the hollow cup micro motor industry/enterprise standards and relevant requirements, energy conversion efficiency is maintained at more than 70%.

3. The formation of 10mm hollow cup mute large torque vibration motor series products, fully suitable for vibration massager and electric toothbrush and other applications, greatly broadens the company's product range, enhance the market competitiveness.

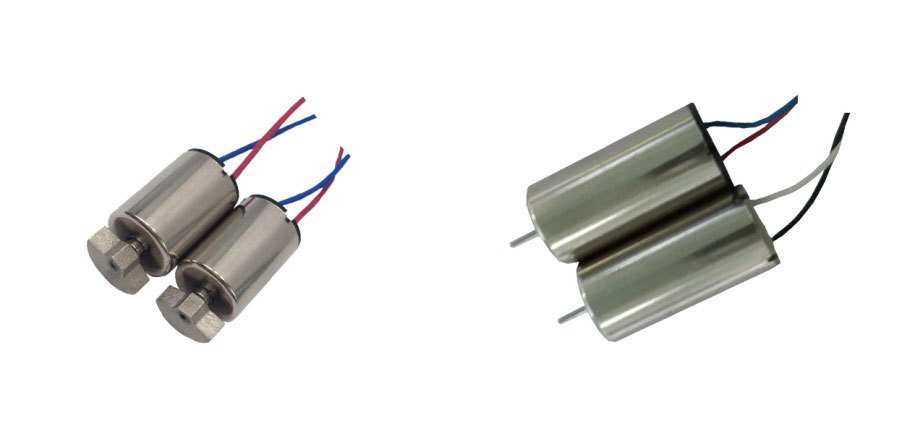

Legend of developed motor

Application Legend

Key words:

Previous Page

Guangdong Chaoli Motor Co.,Ltd.

Here is the title one h1 placeholder text

Address: Xingye East Road, Laimei Industrial Zone, Chenghai District, Shantou City, Guangdong Province

Shenzhen Sales Division

Name: Ms Hu

Mobile:(86) 138 2352 5969

Telephone:(86-755)2721 9096/2721 9696

Mailbox:szcl@chaolimotor.com

WeChat QR Code

Name: Mr. Cai

Mobile: (86) 136 7045 7762

Telephone:(86-754) 8696 2232

Mailbox:Henry@chaolimotor.com

Website:www.chaolimotor.com

WeChat QR Code

Name: Mr. Chen

Mobile:(86) 156 0271 1777

Telephone:(86-754) 8696 2230

Mailbox:cl@chaolimotor.com

Website:www.chaolimotor.com

WeChat QR Code

Main Products

Can't find the service you are looking for? Contact us!

If you need to inquire about our products, please leave your email to us and we will contact you within 24 hours.