Development basis and background

Micro AC permanent magnet generator is suitable for LED light-emitting faucets, self-generating LED showers, top spray and other fields. In addition, it can also be used for hand-cranked flashlights, car wind lights, garden pool lights, small windmill pens; Manual folding (DIY) products, educational products, novelty toys, household appliances and other fields. It can realize the function of converting mechanical energy such as hydraulic/wind power into electrical energy. Compared with the company's main product micro motor, the basic principle is different, the application field is brand-new, environmental protection and energy saving. With the improvement of people's living standard, the demand is expected to be more and more vigorous. The generator is expected to be developed, especially suitable for medium and high-grade shower head spray, and it has the characteristics of compact structure, wide voltage regulation range, long life and low noise.

At present, similar generators sold by peers often fail to meet customer requirements in terms of life and power generation, and product consistency and structural manufacturability are also poor. If the company can seize the opportunity, take this project as a starting point, enter the field of micro-generators, and strive for excellence. Combined with the advantages of technology and talents in micro-motors, it will certainly bring good results and economic and social benefits, thus improving the company's comprehensive competitiveness.

At present, several customers have consulted about such products. If the company carries out the research and development of such generators, it can occupy a new high ground of technology and sales volume in the field of micro-generators, lead the development direction of the industry, and be more agile to meet the individual use and performance requirements of customers and fill the technical gap of the company in micro-generators.

R & D content:

1. Development and design of new structure of micro hydroelectric generator

1) The impeller is arranged to be placed in the upper chamber of the casing as a whole, and the upper chamber is provided with 8 drain ports. Through reasonable design of 3 water inlet ports, the water flow through the ports can promote the rotation of the impeller and maximize the use of mechanical energy;

2) The optimal design of the trunking is carried out, the winding is set in the two trunking on the skeleton body, and the maximum capacity of the trunking of different shapes is calculated. The optimal gap and length between the outer diameter of the magnetic steel and the inner cavity of the skeleton body are designed. When working, the magnet cuts the magnet wire to form a potential difference, thereby obtaining an output;

3) One end of the rotor shaft is provided with a wear-resistant graphite gasket, and both ends are supported by non-metallic PEEK bearings assembled on the skeleton body and the back cover. Through 3D simulation analysis, the entire axial clearance is controlled between 0.05 and 0.3mm, which can greatly improve the service life of the generator;

4) The stator and rotor assembly is arranged in the lower chamber of the housing, and is sealed and isolated by sealant, and can play a fixed role at the same time. On the one hand, it simplifies the assembly structure, on the other hand, it can also reduce the overall noise and improve the reliability of the generator operation.

Main R & D contents and results

2. Study on the assembly process of the generator

1) Study the drawing force performance of different glues between the shaft sleeve and the magnetic steel, between the shaft and the magnetic steel, and between the impeller and the shaft under normal temperature and high temperature (100°C), and then develop the holding glue that best meets the performance requirements;

2) Comparative analysis test of sealant composition. Based on the cost, production efficiency and sealing requirements, the ratio of potting AB glue is optimized;

3) the use of ultrasonic welding end cover assembly, instead of the traditional glue welding process, and optimize the welding time, pressure and other parameters, to further improve the production efficiency and assembly consistency.

3. Study on generator characteristics based on performance requirements

Through the study of the no-load characteristic U = f(n) of the generator; Voltage-current external characteristic U = f(I); Load-power characteristic and output characteristic I = f(n), the best working point and realization way of the constant flow generator are studied by using the principle of dragging. At the same time, the power matching method of load regulation is found, so that the generator can realize its own input between the variable speed impeller and the inverter, the output characteristics are optimally matched with the output characteristics of the variable speed impeller and the input characteristics of the inverter, respectively.

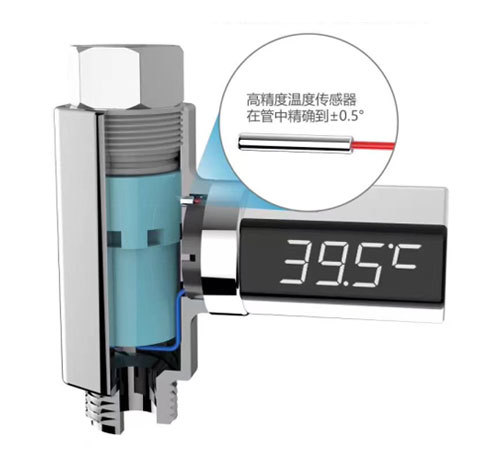

4. Design and development of LED temperature control color-changing light-emitting circuit board

The generator body is equipped with a LED temperature-controlled self-luminous circuit board. The PCBA board is designed with a compact overall structure, connected to the output end of the body, and sealed by transparent epoxy resin glue to form an independent temperature-controlled lighting system, which can achieve:

1. When the AC output voltage of the generator is ≥ 3.0VAC, the LED lamp can start to emit light normally and stably under the water temperature of 0~100°C;

2.PCBA board has good voltage fluctuation stability, LED lights work without flicker, flicker and other bad;

3.PCBA board can realize temperature control color change function, the specific performance is:

1) The water temperature is less than 30°C, and the light of the four LED lights shows blue when working;

2) Water temperature = 30°C ~ 40°C, the four LED lights show green when working;

3) The water temperature is> 40°C, and the light of the four LED lights shows red when working.

R & D Results:

1. Based on the performance requirements of the generator, the new development and design of the stator, rotor and end cover (casing) components of the generator are carried out, and a miniature AC generator with compact structure, high reliability, long service life and low noise is developed to realize the function of temperature control, color change and self-luminous, save electric energy, carry out temperature control tips, realize water temperature visualization and lighting assistance, and increase the interest and beauty during use. The core assembly and process technology of micro permanent magnet alternator is formed.

2. Analysis of relevant data shows that at present, the research on such generators at home and abroad is mainly concentrated on the structural form of generators with a diameter of more than 25~30mm, and the power is large, and the research direction is mainly concentrated in the electronic drive. The main research direction of this project is small diameter (Φ4 ~ Φ25mm) generator, focusing on how to improve the energy density of the generator, and the miniaturization, integration and permanent magnetization of the generator. It can be said that the current domestic research on such motors is still in the initial stage, and the product technology level is at the leading domestic level. It can completely replace imported products, lead the industry's technological development direction, and improve the company's product technology innovation level and market competitiveness.

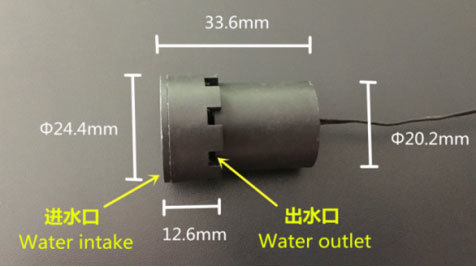

Legend of developed motor

|

|

|

|

Application Legend

|

|

Key words:

Guangdong Chaoli Motor Co.,Ltd.

Here is the title one h1 placeholder text

Address: Xingye East Road, Laimei Industrial Zone, Chenghai District, Shantou City, Guangdong Province

Shenzhen Sales Division

Name: Ms Hu

Mobile:(86) 138 2352 5969

Telephone:(86-755)2721 9096/2721 9696

Mailbox:szcl@chaolimotor.com

WeChat QR Code

Name: Mr. Cai

Mobile: (86) 136 7045 7762

Telephone:(86-754) 8696 2232

Mailbox:Henry@chaolimotor.com

Website:www.chaolimotor.com

WeChat QR Code

Name: Mr. Chen

Mobile:(86) 156 0271 1777

Telephone:(86-754) 8696 2230

Mailbox:cl@chaolimotor.com

Website:www.chaolimotor.com

WeChat QR Code

Main Products

Can't find the service you are looking for? Contact us!

If you need to inquire about our products, please leave your email to us and we will contact you within 24 hours.